|

|

Ash Handling EquipmentBottom ash and flyash are difficult materials to handle. The essential factor for the design of a reliable system is experience. Over the last 25 years, Transdynamics has been designing and building Ash Handling Systems. Many of these projects have been full-scale retrofits where we have replaced systems designed by less experienced firms. Transdynamics ash handling expertise includes handling of both wet and dry ash. Associated areas include flue-gas ducting, ash mixing and conditioning, lime injection, ferrous recovery and ash storage and loadout. |

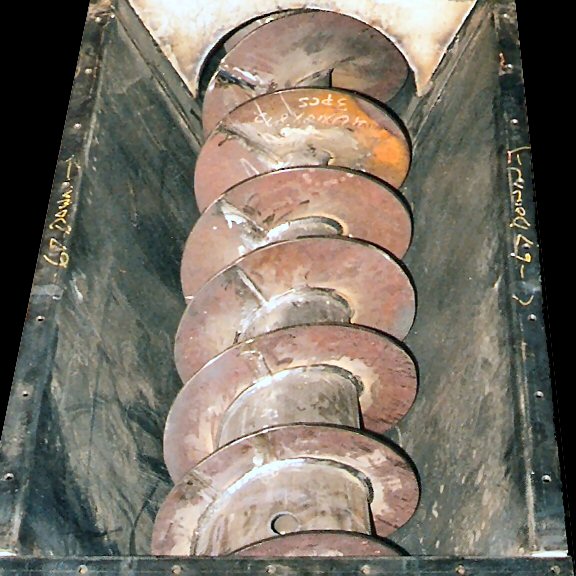

Detail of 18" diameter feed screw used to remove bottom ash from a storage bin. The shaft of the screw is tapered and designed to remove material evenly along its full length. |

Detail of drive sprocket for ship-chain drag conveyor. Ship chain is ideally suited for tough applications handling wet abrasive materials such as bottom ash. |

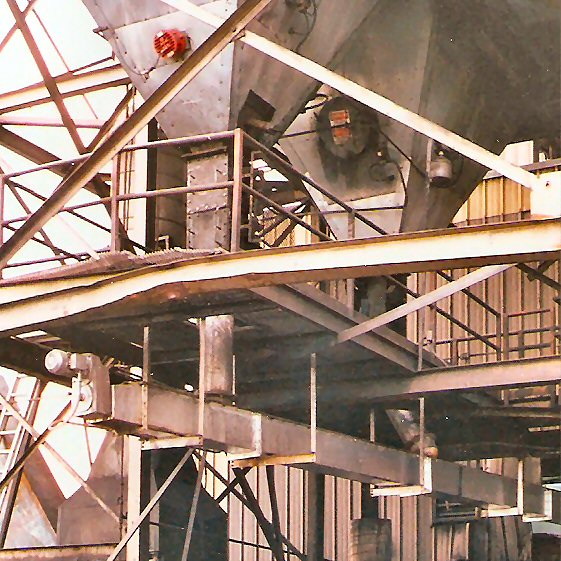

As a part of this retrofit, Transdynamics installed square trough flyash handling screws to minimize wear. Conveyor is suspended on hangers to allow for thermal expansion. |

Motorized Conveyor Belt Cleaner specifically developed for removing wet ash from conveyor belt. This unit is powered by a 3hp motor and cleans 48" wide belt. Unit is adjustable for wear. Brush elements are easily replaceable. |

Material recovered from wet incinerator ash using Transdynamics Ash Ferrous Recovery System. Material is discharged onto a de-watering pad before removal. |

© Transdynamics, 2023